Supply Chain

Every trend in hardwood manufacturing, especially at the primary manufacturing level, points to fewer players and increased efficiencies in the supply chain.

Hardwoods take a long time to grow and are a difficult resource to procure, and a great deal of the costs involved in its production are in the harvesting and transportation of the raw material. Therefore, a huge priority must be placed on locating the manufacturing facility as close as possible to the resource. But, it’s not the only consideration. Attention must be paid to local demand, competition for the resource; the infrastructure required for transportation, and a regulatory climate that does make it difficult to do business or supports anti-forestry causes.

Also, with more countries and companies demanding certified wood from verified sustainable forests, the supply chain can be complicated by strict (and sometimes expensive) requirements including annual audits and chain-of-custody tracing. Indiana has addressed that issue by some degree by offering limited certified wood from our state forests and from private landowners enrolled in the Classified Forest and Wildlands program.

Hardwood product consumers desire such a broad range of products that we are able to utilize all grades of timber. From lumber to veneer, to furniture, flooring, animal bedding, pallets, railroad ties, paper, and so much more, there are markets for our wood.

Over a couple of centuries, and especially with the reforestation of Indiana for the last 90 years, our state could not be MORE perfectly positioned for supply chain efficiency. To illustrate the point, let’s first take a look at the players in the hardwood supply chain.

Forest Landowners

You can check this box. Over 20% of Indiana’s land base is currently in forests, and 85 percent of that potential commercial timber supply is in the hand of private landowners. Most of the rest is in state or federal ownership, only a small fraction of which can be managed for timber production. But make no mistake. Indiana has an abundant and sustainable timber resource, with a broad range of species and grades available.

Loggers

We’ve got plenty of those too, but the reality is that the median age of our loggers is getting older, and its increasingly difficult for new, young loggers to enter the business, unless they were born into it or have significant financial resources at the start. It’s deadly and dangerous work, for relatively low pay, with crappy hours and weather unpredictability. Mechanized harvesting is slowly replacing traditional logging, but for supply chain purposes, we have the workforce to extract the raw materials once the timber sale has been completed.

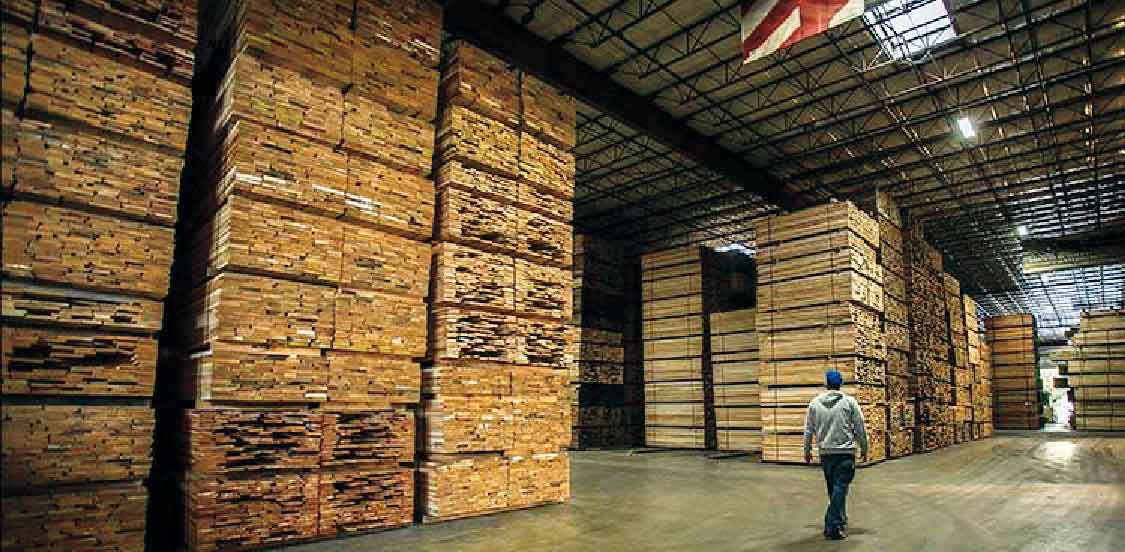

Primary Manufacturing

Although the numbers of operations decline, manufacturing capacity for lumber and veneer remains very high in Indiana. With most mills still being relatively small, family-owned independent businesses, the purchasing and production decisions are still done company-by-company, leading to inevitable volatility in price, and an increased emphasis on balancing stumpage prices with lumber prices. As we move toward fewer, bigger companies, analytics and economies of scale will create a more disciplined, predictable and numbers-driven purchasing environment, and real-time data will replace surveys of mills for driving final timber price decisions. Species demand and competition for logs will still rule the day, and it’s important that we manage forests to protect that diversity.

Distributors

Distributors still play a key role in consolidating lumber produced from so many smaller sources and reselling it along to the secondary markets. The drying, sorting, and quantity-accumulating capability creates predictability of supply and price for those secondary markets who are making furniture, cabinets, flooring and more. Without huge parcels of land and large-scale timber sales, they are a collection point for many small quantities of lumber coming from both public and private lands via the primary manufacturers.

Secondary Manufacturing

We have them in abundance in Indiana as well. Cabinets, office furniture, stave mills, casket manufacturers, recreational vehicles, and pallet manufacturers are among those who comprise a vertically-integrated link of companies who keep demand high for a wide variety of grades and species.

End Users

Homeowners need furniture, flooring, cabinets, mulch, paper goods and wood trim. Farmers need animal bedding, and bourbon makers need barrels. Railroads need ties, distributors need pallets. Indiana is within a day’s drive of 75% of the U.S. population, and we are sitting on a reserve of renewable forestland that can be shipped to consumers around the globe. Check the last box in the supply chain to drive home the point that we are perfectly positioned to be a world leader in hardwoods.

So, bottom line – the supply chain is going to get more efficient, faster, more agile and more customizable with advances in technology and sizes of operations, but as long as we understand the roles of both private and public forestland management, Indiana can always remain an ideal place to grow and sell timber. What could threaten such a no-brainer of a sustainable economic driver?

Like any chain, the threat to our supply chain would be its weakest link. The loss of any one of its links would be felt throughout the entire chain. COVID-19 has caused a disruption in our economy, but it can be used to illustrate the point.

Economic uncertainty, and job losses affect the housing markets. Banks don’t lend money to those without jobs, and stock market losses make consumers gun-shy about spending. Reduced demand for wood results in lower timber prices to private landowners. While private landowners wait for better selling markets, the timber that comes off our state forest and national forest land and timber bought before the economic downturn can help augment supplies and balance species mixes at the distributor level as markets recover, keeping the chain from breaking.

Indiana is perfectly positioned to maintain an efficient hardwood supply chain. Woodland owners are the foundation, public lands support and diversify hardwood supplies and the forest products industry is continuing to develop efficiencies and technological advances to keep the hardwood supply chain in Indiana resilient and viable into the future.

Ray Moistner is executive director of the Indiana Hardwood Lumbermen's Association. The IHLA Works to ensure a sustainable, affordable supply of quality North American hardwoods for the public good.